Flowmeters and dosing pumps ensure accurate flow measurement and precise chemical dosing in treatment systems. These devices help maintain process control, optimize chemical usage, and improve overall plant efficiency.

- Accurate flow measurement

- Controlled chemical dosing

- Improves process stability

Flow Meters

| Type | Electromagnetic Flow Meters | Ultrasonic Flow Meters |

|---|---|---|

| Measurement Method | Conductive liquid via magnetic induction | Non-contact via transit-time or Doppler ultrasound |

| Pipe Size Range | 25 mm to 600 mm | 15 mm to 2000 mm |

| Accuracy | ±0.5% of reading | ±1% of reading |

| Mounting | Flanged, inline | Clamp-on (external) |

| Conductivity Required | Yes (≥ 5 µS/cm) | No (any clean or dirty liquid) |

| Output | 4–20 mA, Pulse, RS485 (MODBUS) | 4–20 mA, Pulse, RS485 (MODBUS) |

| Display | Local LCD (Totalizer & Instant Flow) | LCD with keypad display |

| Power Supply | 230 VAC / 24 VDC | 230 VAC / 24 VDC |

| Enclosure Rating | IP65 / IP67 / IP68 | IP65 standard |

| Applications | STP inlet/outlet flow, chemical dosing, treated water | Treated water, retrofit pipelines, chemical lines |

Raw Water Pump

Pumps used to transfer water from source to plant

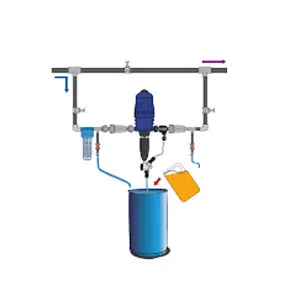

Dosing Pumps

For chlorine, alum, Antiscalant, etc.

Chlorine Dosing System

For disinfection