Trusted Sewage Treatment Plants, Mechanical Bar Screens, Oil Skimmers, Flow Meters, MBBR Media, Tube Settlers, Chemicals for Sewage Treatment Plants Manufacturer, Supplier & Exporter from Pune, Maharashtra, India.

Mechanical Bar Screen

| Bar Spacing (mm) | Material | Operation Type | Flow Range (m³/hr) |

|---|---|---|---|

| 25–50 | MS Epoxy Coated | Manual | 5–50 |

| 15–30 | SS304 | Mechanical | 50–250 |

Oil Skimmers

| Belt Width (mm) | Oil Removal Capacity (LPH) | Material | Mounting Type | Power (HP) |

|---|---|---|---|---|

| 100 | 5–10 | SS304 / MS-FRP | Wall Mounted | 0.25 |

| 200 | 15–30 | SS304 / MS-FRP | Tank Mounted | 0.5 |

| 500 | 50–75 | SS304 | Custom Frame | 1.0 |

Flow Meters

| Type | Electromagnetic Flow Meters | Ultrasonic Flow Meters |

|---|---|---|

| Measurement Method | Conductive liquid via magnetic induction | Non-contact via transit-time or Doppler ultrasound |

| Pipe Size Range | 25 mm to 600 mm | 15 mm to 2000 mm |

| Accuracy | ±0.5% of reading | ±1% of reading |

| Mounting | Flanged, inline | Clamp-on (external) |

| Conductivity Required | Yes (≥ 5 µS/cm) | No (any clean or dirty liquid) |

| Output | 4–20 mA, Pulse, RS485 (MODBUS) | 4–20 mA, Pulse, RS485 (MODBUS) |

| Display | Local LCD (Totalizer & Instant Flow) | LCD with keypad display |

| Power Supply | 230 VAC / 24 VDC | 230 VAC / 24 VDC |

| Enclosure Rating | IP65 / IP67 / IP68 | IP65 standard |

| Applications | STP inlet/outlet flow, chemical dosing, treated water | Treated water, retrofit pipelines, chemical lines |

MBBR Media

| Parameter | Specification |

|---|---|

| Size | 12 x 25 mm |

| No. of Holes | 19 |

| Surface Area | >500 m²/m³ |

| Density | 0.94 – 0.96 gm/cm³ |

| Porosity | >90% |

| Dosing Ratio | 15 – 65% |

| Membrane Forming Time | 3 – 15 Days |

| BOD Oxidation Efficiency | 2000 – 10000 gm/m³ |

| COD Oxidation Efficiency | 2000 – 15000 gm/m³ |

| Applicable Temperature Range | 5°C – 60°C |

| Life Span | >10 Years |

| Material of Construction (MOC) | Virgin HDPE |

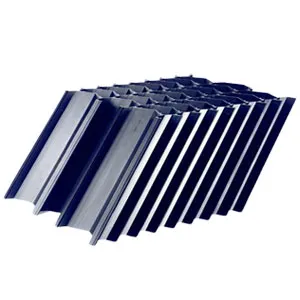

Tube Settler

| Parameter | Specification |

|---|---|

| Plan Settling Area | 60° Slope: 11 m²/m³, 55° Slope: 13 m²/m³ |

| Hydraulic Radius | 15 mm |

| Cross Sectional Area | 120 mm x 44 mm |

| Color | Black |

| Material of Construction (MOC) | PVC |

| Thickness | 1 mm Approx. |

| Fitting Arrangement | Tongue & Groove |

| Max. Continuous Operating Temp. | 55° C |

Chemicals for STP – Trading Catalogue

| Chemical Name | Purpose / Application | Form | Typical Dosage Range |

|---|---|---|---|

| Alum (Aluminum Sulphate) | Coagulant for suspended solids & turbidity removal | Powder / Lumps | 10 – 50 mg/L |

| TCCA-90 (Trichloroisocyanuric Acid) | Disinfection of treated sewage / water (chlorine source) | Tablets / Granules | 1 – 3 ppm (mg/L) in outlet water |

| Bacta Culture (Bio Culture) | Enhances microbial population for BOD/COD degradation | Powder / Liquid | 2 – 5 ppm (start-up), then 1 ppm/day |

| Food for Bacteria (Urea + DAP mix) | Nutrient for sustaining bacteria in biological treatment | Granules | Urea:DAP = 2:1 ratio, 3 – 5 ppm |